Test bed

A test-bed environment is currently under development at the Integrated Systems Facility and the Embedded System & Networking Laboratory of the Auto-ID Research Group. The objective is to demonstrate the potential benefits of Auto-ID technologies at various levels in a manufacturing enterprise, from shop floor level real-time operations to supply chain level business processes.

We envision that the test-bed will be utilized to achieve the following goals:

1. Models and algorithms that we are developing as a part of our research agenda can be effectively tested and validated in a short time, which adds value to our academic work.

2. Different hardware and software tools provided by our industry partners can be tested and benchmarked in a real life-like, industrial setting.

3. Based on the first two goals, we can design and develop new tools that can provide viable solutions to the industry.

In order to achieve these goals, we have laid out an effective plan for design, development, and implementation of hardware and software modules that can be integrated in a flexible manner. Our plan includes three phases:

Phase 1 - Simulation Models

Manufacturing system simulation and network simulation models have been developed in order to analyze the effectiveness of different decision making algorithms that rely on Auto-ID data. The primary objective in this phase was to investigate how low-cost preliminary testing, in order to eliminate some of the decision making algorithms that do not lead to desired level of manufacturing system performance, as well as network performance, can be carried out without relying on any Auto-ID hardware.

We are using Rockwell Automation ARENA simulation package for manufacturing system simulation and NS Simulator for network simulation.

Phase 2 - Hardware-in-the-loop Simulation Models

The decision making algorithms that were tested and found to be effective in Phase 1 are further investigated in a hardware-integrated simulation environment in order to detect possible hardware-related problems. This phase provides insights for improving the decision making models, as well as networking protocols.

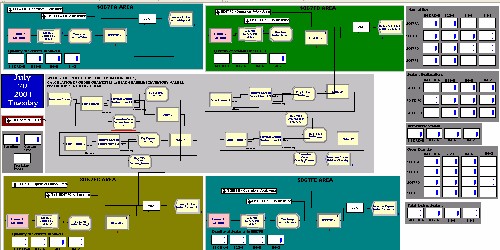

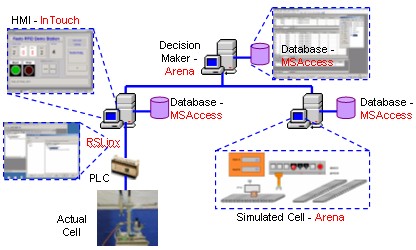

The model shown above includes a PLC (programmable logic controller) controlled pick-and-place unit (shown as "Actual Cell"), a simulated cell, a higher level decision maker that synchronizes the operation of the actual and simulated cells, and a human-machine interface (HMI) that monitors the status of the actual cell. In this environment, various software and hardware tools have been integrated to perform as a system. ARENA simulation software has been used in a non-traditional way; it is used as a cell controller that runs in real-time and controls actual equipment.

Phase 3 - Hardware-intensive Testing Environment

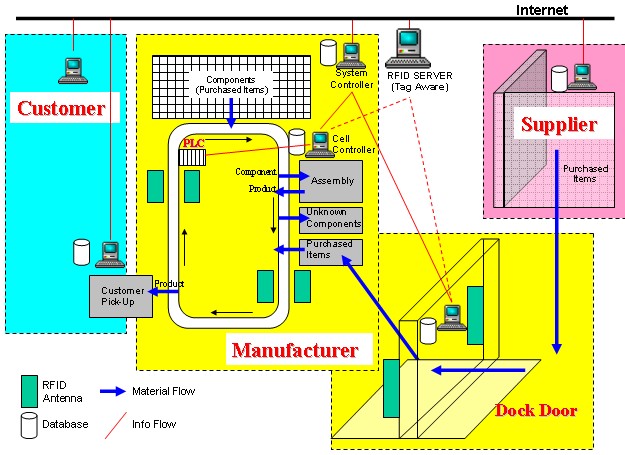

This phase aims to integrate, in the most realistic way, all the possible hardware and software modules in order to validate the true effectiveness of decision making algorithms that have already been filtered through Phases 1 and 2. In this phase, we are currently working on developing an environment for “Integrated Supply Chain and Shop Floor Management Using RFID Data”. As shown below, the manufacturing environment includes two robots, a CNC milling machine, a conveyor, an automated storage & retrieval system, and a dock door (below left).

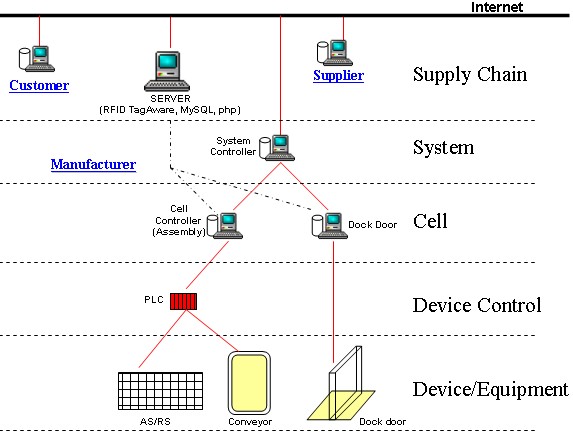

The overall application and the control architecture to facilitate various operations are shown below.